| Precision | Blackbodies |

The Rapid

Heating Concept |

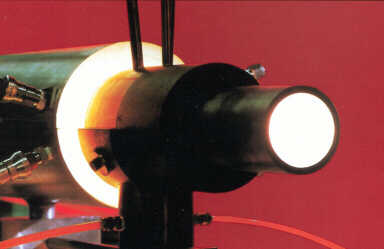

The design and heating concept employed in our graphite tube furnaces is what we call "Rapid Heating". It is based on the principle of quick, direct resistance heating of a graphite heater element using high AC current to put large amounts of power into a heater element. The graphite heater element heat up rapidly and it is poorly insulated so that it can cool down almost as quickly as it heats. Fast heat up times are enhanced by using much larger power supplies than those normally associated with furnace elements of the sizes used in these furnaces. Water-cooling helps speed cool down. Argon purge helps cool too, but mostly protects the graphite. Stability at temperature is achieved by using a very sensitive radiation pyrometer to measure cavity temperature and fast responding, precision feedback, digital control of the heater currents. The net result is a very stable furnace that can be run up and down in temperature in minutes, rather than hours as in those conventional, highly insulated sources sold by others. The benefit is a virtual workhorse; a productive device that can save days in performing calibrations and verifications of infrared instruments and radiation heat flux gauges. Check the product specification pages, you'll be amazed at the time to equilibrium our designs achieve. | |

| Precision Blackbodies Laboratory blackbodies approximate Max Planck's ideal. We strive to provide the closest approximation that a reasonable budget and the needs for precise sources of Blackbody thermal radiation can provide. | ||

|

Copyright

2003 Thermo Gauge Instruments, Inc. , All rights reserved | ||