MODEL

HT-7000A

Graphite Tube Blackbody Temperature Controller

Features:

- A 4 line by 20 character LCD display that simultaneously shows:

- Black body temperature in °C, °F, or K with 0.1° resolution.

- Set

point temperature in C, °F or K with 0.1° resolution.

- Set point step

size.

- Output hold flag.

- Set point increments of

1, 10, and 100 °C

- Set point is changed by either using the numerical

keypad or by pressing the increment and decrement keys. Pressing the increment

or decrement key will change the set point by the amount of the set point increment.

- A standard RS-232 port is provided to allow connection to a computer

and can be used for:

- Monitoring blackbody temperature

- Changing

set point.

|

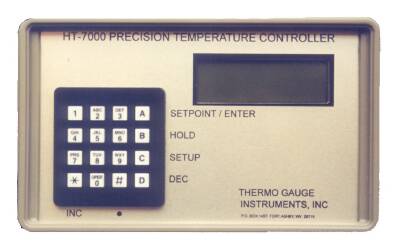

Controller

Front Panel with Keypad

(NB: Model 7000 shown appears almost

identical to Model 7000A) |

DESCRIPTION

The

model HT-7000A is a high precision, three-term, Proportional, Integral, Derivative

(PID) furnace controller specifically designed for the Thermo Gauge Brookley tube

furnace. It uses as a control input, the cavity temperaturedital output from an

automatic optical pyrometer. The combination of the HT-7000A controller and the

Exactus pyrometer makes a highly repeatable, highly stable system that is used

for precision high temperature work. The

controller operates stand-alone and is dedicated to maintaining the temperature

of the blackbody. An RS-232 port is provided to allow the user to monitor the

status and temperature of the blackbody and to change the temperature set point.

The controller has a temperature resolution of 0.1° and controls the furnace temperature

to ±0.1 ° C over most of the temperature range (±0.3° C at the

extremes). The

use of an alphanumeric display screen simplifies the operation of the furnace

and assists the operator by a series of screen prompts.

INPUTS

AND OUTPUTS INPUTS:

The input to the

HT-7000A is located on the rear panel of the controller. The input is a plug and

is designed to connect to the pyrometer. OUTPUTS: The

output of the HT-7000A controller is located on the rear panel of the controller

and is a shielded circular DIN Standard connector. This output connects to the

furnace "EXTERNAL INPUT" and is the 0-5V-DC signal that controls the power level

of the furnace. DUAL

PORT : There

is one dual input/output port on the HT-7000A. It is located on the rear panel

of the controller. It is a standard DB-9 connector and operates at RS-232 logic

voltage levels. This port is used to interface to a computer for remote control

of the furnace or for data recording. FRONT

PANEL CONTROLS

SET POINT: To

change the set point, press the set point key, enter the new set point then press

the key again. SETUP: Setup

is used to select three things 1.

STEP SIZE - selects the set point step size in the same units that are selected.

When in the setup mode and 1 is pressed the step size changes to the next predefined

value. 2.

UNITS - select the units for the system, °F, °C, K. When in the setup mode and

2 is pressed the units change to the next unit in the list. 3.

RAMP - selects the predefined ramp rate. When in the setup mode and 3 is pressed

the ramp rate changes to the next value in the list. |

INC

and DEC: The

"INC" (increment) and "DEC" (decrement) keys are used to increase or decrease

the set point. When the "INC" key is pressed the set point will increase by the

selected step size. When the "DEC" key is pressed the set point will decrease

by the selected step size. HOLD:

The "HOLD" key

is used to hold the output of the controller at its present value. When "HOLD"

is pressed the controller is disabled and the output is held at its present value.

When "HOLD" is pressed a second time the controller will begin controlling at

the present temperature. This is useful in special applications when the control

loop must be interrupted. BLACKBODY

CONTROL Following

the appropriate procedures in the furnace operation manual align the Exactus optical

pyrometer with the blackbody at the proper focal length. Connect the output of

the Exactus to the HT-7000A. The system is now ready for operation. Turn

on the HT-7000A. The default settings are set point = 800°C and step size = 100.0°C. If

the furnace power supply is on and all interlocks are clear the furnace will heat

and stabilize at 800 °C. After

the system is stable at 800°C the set point can be changed by pressing the "INC"

or "DEC" keys or by entering a set point on the keypad. If the "INC" or DEC" keys

are used, the set point will change by the step size. Step size is indicated in

the LCD display. To

shut down the system press the "Stand by" button on the furnace power supply.

When the black body has stopped glowing and is dark black, turn off the purge

gas. After the black body has been dark for 5 minutes, turn off the cooling water.

Then turn off the HT-7000A. INTERFACING

TO A COMPUTER The

HT-7000A can be interfaced to a computer that has a standard RS-232 port. The

RS-232 port is configured as baud rate = 19600 bps, no parity, 1 start bit and

1 stop bits. The communication has no handshaking and uses a standard 1to1 DB-9

cable. The

HT-7000A continuously sends ASCII string data out the RS-232 port; data sent is

temperature in degrees C. The ASCII format is universal and easy to interpret. |

|